referanslarımız (42)

Children categories

541.225.000 adet/yıl KIRŞEHİR/TÜRKİYE

Steel structure

Steel structure

High/low pressure process piping fabrication and installation

Equipment installation lnstrumentation

3 x 38.5 tons/hoursteam capacity

Boilerfabrication and installation

Precommissioning , commissioning

and start-up

Ope ration, maintenance and repairworks forthree years with more than 500 personnel

Tyre wagons fabrication and installation

TECEN / TÜRKMENİSTAN

Ammonia: 600 tons/dayUrea: 1050 tons/day Ammonia Complex: 13 Units

Urea Complex: 8 Units Auxiliary System :12 Units Steam Boiler : 145 Vh

Power Generator: 2x18,75 MVA Mechanical Erection Works:

• Synthesis and Production Units

• Boiler

• Reformer

• Turbine& Compressors

• High/LowPressure Piping

• Water Treatment System

• Auxiliary Units

• Refractory &Rubber Lining

• Stacker &Reclaimer

• Steel Construction

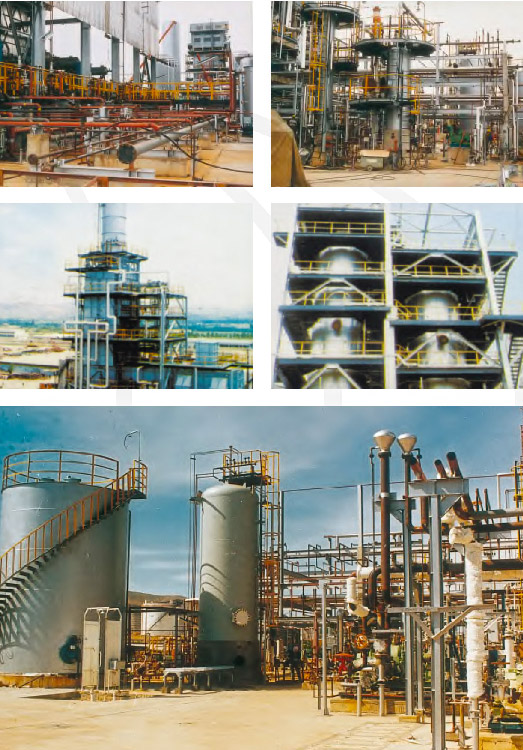

RAFİNERİ VE PETROKİMYA TESİSLERİ

TÜPRAŞ Kırıkkale Rafinerisi

TÜPRAŞ Kırıkkale Rafinerisi  TECEN Amonyak ve Üre Tesisi

TECEN Amonyak ve Üre Tesisi  Petlas Lastik Fabrikası

Petlas Lastik Fabrikası  TÜPRAŞ Aliağa Rafinerisi

TÜPRAŞ Aliağa Rafinerisi  TÜPRAŞ İzmit Rafinerisi

TÜPRAŞ İzmit Rafinerisi  İran Arak Rafinerisi

İran Arak Rafinerisi

KIRIKKALE / TURKEY

The design, supply, construction and erection services of project have been fulfilled on turnkey lump sum basis by consortium of TEKNOTES and SOFRESID S.A./France. The Provisional Acceptance of the project has been attained in 1997 and the Final Provisional Acceptance in1999. in addition to the complete detailed design and partial basic engin nering, all construction and erection services, alsa the supply of steel structure, static equipments (Heat exchangers,Drums , Adsorbers , Columns ete.), electrical equipment and materials ete. have been carried aut by TEKNOTES. At the piant, the low Octane Number Naphtha is used as raw material and unleaded gasoline is produced as end product.

The design, supply, construction and erection services of project have been fulfilled on turnkey lump sum basis by consortium of TEKNOTES and SOFRESID S.A./France. The Provisional Acceptance of the project has been attained in 1997 and the Final Provisional Acceptance in1999. in addition to the complete detailed design and partial basic engin nering, all construction and erection services, alsa the supply of steel structure, static equipments (Heat exchangers,Drums , Adsorbers , Columns ete.), electrical equipment and materials ete. have been carried aut by TEKNOTES. At the piant, the low Octane Number Naphtha is used as raw material and unleaded gasoline is produced as end product.

TÜPRAŞ KIRIKKALE RAFİNERİSİ HYDROCKER TESİSİ

Yüksek / alçak basınç proses borulama imalatı ve montajı

Yüksek / alçak basınç proses borulama imalatı ve montajı

Çelik konstrüksiyon imalatı ve montajı

İnşaat işleri Döner ekipman montajı

Elektrik ve enstrümantasyon Refakat hatları imalatı ve montajı

Ex-Proof Tavan Vinci imalat ve montajı

Ekipman Montajı

Rewamp ünitesi imalatı ve montajı

Detay mühendislik

2x330 MW MARITZA THERMA L POWER PLANT - BULGARIA

Written by Super User2x330/GALABOVO / BULGARIA

2 x 150 MW KANGAL / SIVAS / TURKEY

Boiler erection

Boiler erection

High/low pressure proses piping fabrication and installation

Off-site piping fabrication and installation

Civil works

Rotary equipment erection

Electrical works and instrumentation

Equipment installation

Fabrications and installations in the machine hail

Fabrication, supply and installation of mud scrappers tor raw water intake pools

9 x 150 MW AMBARLI / ISTANBUL / TURKEY

Mechanical Works

Electrical

lnstrumentation and comtrol

High/low pressure proses piping fabrication and installation

Steel structure fabrication and installation

2*160 MW ÇAYIRHAN / ANKARA / TÜRKİYE

5x120 MW/RABIGH / Saudi Arabia

More...

2 x 150 MW ZONGULDAK / TURKEY

Boiler erection

Boiler erection

High/low pressure proses piping fabrication and installation

Off-site piping fabrication and installation

Steel structure fabrication and installation

Electrofilters and dust precipitators fabrication and installation

Civil works

Rotary equipment erection

Electrical works and instrumentation

Equipment installation

Fabrications and installations in the machine hail

Fabrication, supply and installation of mud scrappers tor raw water intake pools

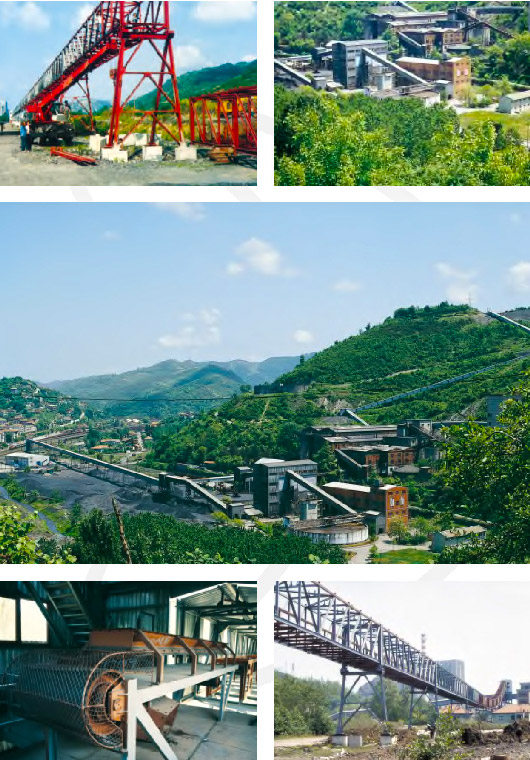

CATALAGZI THERMAL POWER PLANT SLUDGE DEWATERING AND COAL MIXING-WASHERY PLANT WITH LONG DISTANCE BELT CONVEYOR

363560 m, 400 tons/h CATALAGZI/ ZONGULDAK / TURKEY

Length 3560 m

Length 3560 m

3560 m, 400 tons/hour

Steel structure fabrication and installation

Rotary equipment erection

lnstrumentation

Medium-Tensile and Low-Tensile (MV/LV)electrical installation works

Equipment erection

Commissioning

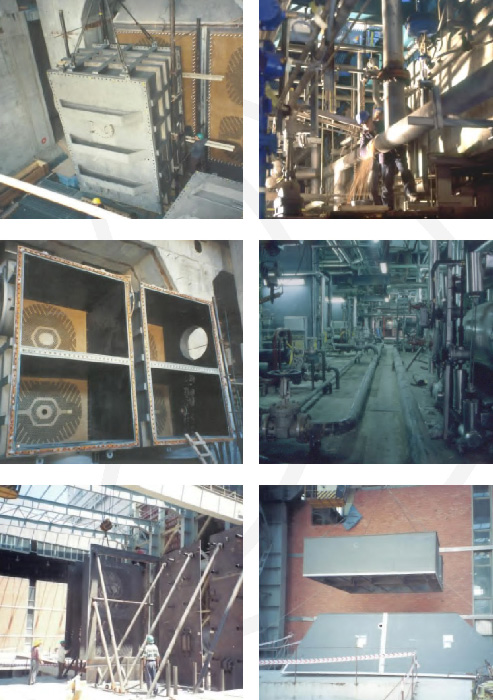

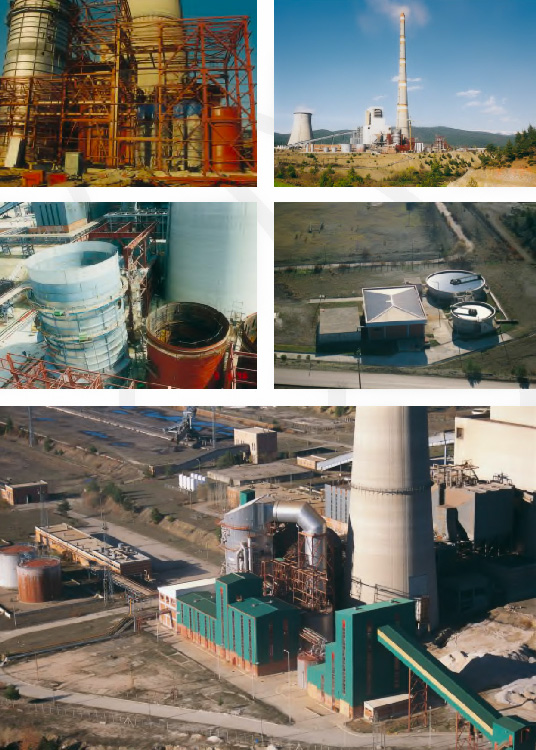

ORHANELİ THERMAL POWER PLANT FLUE GAS DESULPHURIZATION PLANT

Written by Super User1 x 210 MW-BURSA-TURKEY

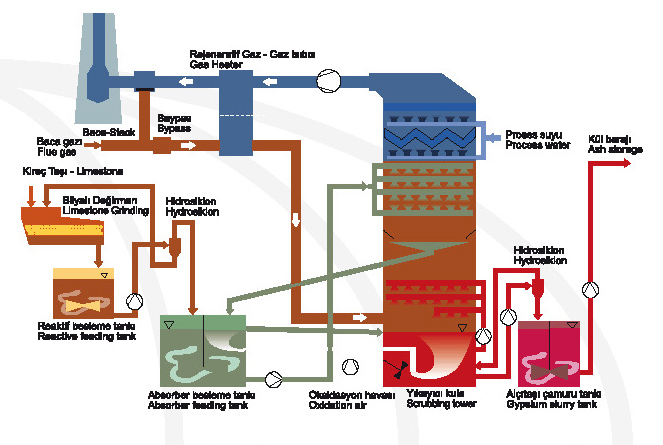

1 x 21O MW Orhaneli Thermal Power Plant Flue Oesulphurization Plant was constructed by the consortium TEKNOTES and NOELL - KRC / Germany and put into operation on 21.11.1997.The limestone wet scrubbing process retrofitted to the Orhaneli Power Plant is the most common commercial process in the world for a like power plants. A limestone powder water slurry is the scrubbing medium and gypsium slurry is the end product. The plant has SO, removal efficiency of 95%. TEKNOTES SO, has implemented all detail engineering, civil works, ıocal material supply, mechanical and equipment erection, process piping, raw water treatment plant, electrical material supply and installation, instrumentation and commissioning activities forthis plant.

1 x 21O MW Orhaneli Thermal Power Plant Flue Oesulphurization Plant was constructed by the consortium TEKNOTES and NOELL - KRC / Germany and put into operation on 21.11.1997.The limestone wet scrubbing process retrofitted to the Orhaneli Power Plant is the most common commercial process in the world for a like power plants. A limestone powder water slurry is the scrubbing medium and gypsium slurry is the end product. The plant has SO, removal efficiency of 95%. TEKNOTES SO, has implemented all detail engineering, civil works, ıocal material supply, mechanical and equipment erection, process piping, raw water treatment plant, electrical material supply and installation, instrumentation and commissioning activities forthis plant.

PROCESS SCHEME

ORHANELİ TERMİK SANTRALİ KÖMÜR PARK MAKİNESİ MONTAJI VE İŞLETMEYE ALINMASI

770 tons/hour BURSA / TÜRKİYE

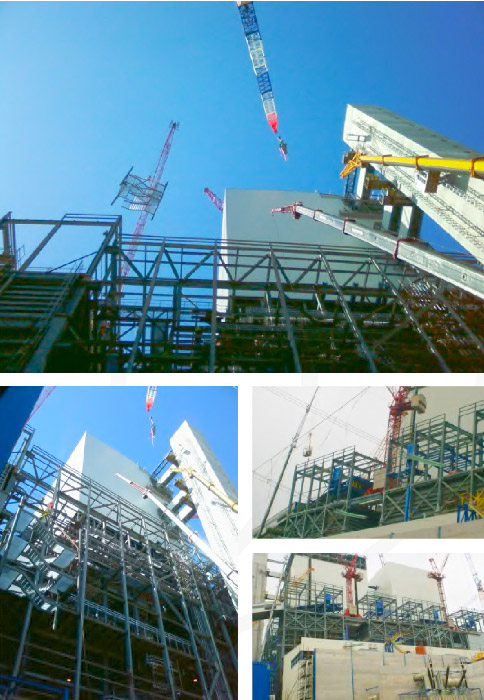

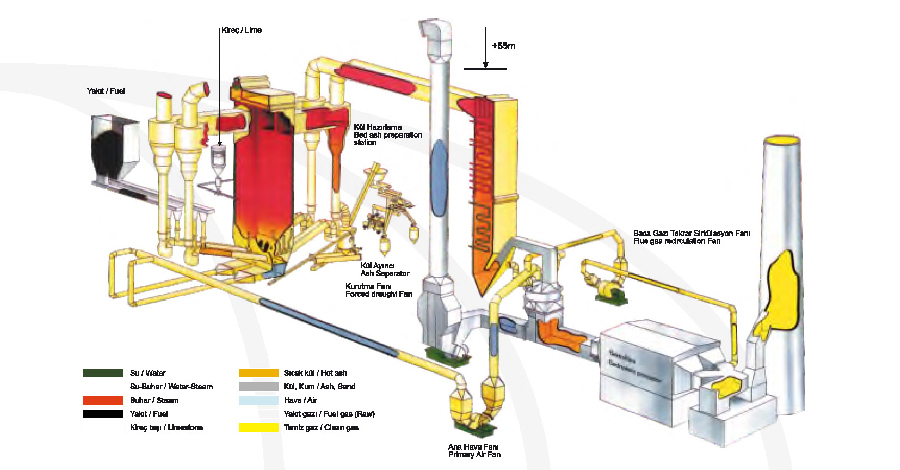

ÇANAKKALE ÇAN FLUIDIZED BED THERMAL POWER PLANT 320 MW

Written by Super User

This project is included in the investment program in 1996 in order to use the 70,000,000 tons highsulphur lignite coal reserve located 1996 near Can for power generation purposes and to meet the ever-increasing domestic demand for energy.

CHARACTERISTICS OF PLANT

STEAM GENERATOR

|

|

STEAM TURBINE

|

Manufacturer: ALSTOM POWER

|

GENERATOR

|

Manufacturer: ALSTOM POWER |

BOILER PROCESS SCHEME |

|

SCOPE OF TEKNOTES

Projeci Managementfor its part

Construction Management

Basic and Detail Engineering

Procurement

Manufacturing of Steel Structure

Manufacturing of Ducting System

Commissioning

AII civil construclion activities

Excavation and backfilling fora total of 2.500.000 cubic meters Substructure and superstructure works fora total of 70.000 cubic meters concrete foundations

Asphalt pavement access roads fora total of 2500 cubic meters lnternal concrete road and pavementfor atotal of 37.000 sq. meters Reinforced Concrete bridge lenghtfor atotal of 50 meters

4 pieces of limestone silos, each capacity 6000 cubic meters (sliding forework system, silo diameter 14 meters, height 36 meters)

Ash disposal area 200.000 cubic meters filing embankment 8 pieces logistics bulding (non-technical buildings)

9000 sq. meters total closed area of buildings

6000 meters service road and open drainage channel

500 meters bored piles diameter 80 centimeters, lenght 12 meters

2 pieces chimney (corten steel) diameter 4,5 meters, height50 meters AII architectural works

Furnishings ofthe buildings

AII Mechanical Erection Works lora total of 42.000 !ons including

Boilers with all accessories Electrostatic precipitars

Turbine And Generator sets with all accessories Rotating machines

Fabricating Equipments

Coal , Ash and Lime Handling Systems Storage Tanks

WaterTreatmentPlants Handling Equipments FOSystems

LP, MP, HP lndoor and Outdoor Piping Fire Fighting and Extinguishing System

Gas Production plants, compressed air plants, auxiliary boiler packages, workshop and laboratories equipments

and other miscellaneous equipments. Steel Structure

HVAC

Refractories

Heat and sound lnsulation Cladding

Painting

AII Electrical Works including

Complete MW/LWSwitchgear System 21 pieces MW/LWTransformers

86.000 meters Cable Tray

700.000 meters Cabling

All lnstrumentation and Control Works Pre-Commissioning

Participating in commissioning and start-up

TEKNOTES ENERGY PRODUCTION PLANTS

320 MW Çan fluidized bed thermal plant

320 MW Çan fluidized bed thermal plant  2*330 MW Maritza Thermal Power Plant

2*330 MW Maritza Thermal Power Plant  5*120 MW Rabigh Thermal Power Plant

5*120 MW Rabigh Thermal Power Plant  210 MW Orhaneli Thermal Power Plant Flue Gas Desulphurization Plant

210 MW Orhaneli Thermal Power Plant Flue Gas Desulphurization Plant  2*150 MW Catalagzi Thermal Power Plant

2*150 MW Catalagzi Thermal Power Plant  2*160 MW Cayirhan Thermal Power Plant

2*160 MW Cayirhan Thermal Power Plant  2*150 MW Kangal Thermal Power Plant

2*150 MW Kangal Thermal Power Plant

REFINERY AND PETROCHEMICAL PLANT

Kişladağ Gold Mine

Kişladağ Gold Mine  Karabuk Air Seperation Plant Construction And Installation

Karabuk Air Seperation Plant Construction And Installation  Sinter II. Plant turnkey Const&Relocation Works Of Isdemir

Sinter II. Plant turnkey Const&Relocation Works Of Isdemir  Erdemir Gas Holder Tank Fabrication And Installation

Erdemir Gas Holder Tank Fabrication And Installation  Erdemir Gas Holder Tank Fabrication And Installation

Erdemir Gas Holder Tank Fabrication And Installation  Sivas Iron And Steel Factory

Sivas Iron And Steel Factory  Iskenderun Iron&Steel Factory Blast Furnace Dedusting System

Iskenderun Iron&Steel Factory Blast Furnace Dedusting System

NATURAL GAS & OIL PIPELINES AND TANK FARMS

WATER TREATMENT PLANTS/WASTE WATER TREATMENT PLANTS

Ajjman Waste Water Treatment Plant And Pipelines

Ajjman Waste Water Treatment Plant And Pipelines  Chlef Waste Water Treatment Plant- Algeria

Chlef Waste Water Treatment Plant- Algeria  Rigga Waste Water Treatment Plant

Rigga Waste Water Treatment Plant  Turkmenebad Water Treatment Plant

Turkmenebad Water Treatment Plant  Sana'a Sewage Project

Sana'a Sewage Project

AIRPORT PROJECTS

Ataturk Airport International Terminal Baggage Handling System

Ataturk Airport International Terminal Baggage Handling System  Bodrum -Milas Airport New International Terminal Building Construction

Bodrum -Milas Airport New International Terminal Building Construction

MASS HOUSING PROJECTS-SHOPPING MALLS-TRADE CENTERS

- reference

- teknotes

- teknotes referanslar

- teknotes reference

- teknotes teknolojik tesisler

- power plant

- enerji tesisleri

- termik santraller

- enerji üretim tesisleri

- havalimanı

- havalimanı inşası

- doğalgaz çevirim tesisi

- rafineriler

- petrokimya

- petrokimya tesisleri

- sanayi

- sanayi tesisleri

- petrol boru hattı

- doğalgaz boru hattı

- doğal gaz boru hattı